- en

NATURAL GAS CHP POWER PLANTS

Series "Lombardia"

Natural gas CHP

Natural gas CHP power plants with use of high electrical efficient turbomachinery (Joule cycle) combined with recovery boilers. High reliability Power Plant model suitable for district heating plants with electrical power higher than 4 MWel. Can be further enhanced upon request through integrated fresh-air module and/or integration boilers up to a maximum thermal power of 10 times that of electric power. For a good profitability, district heating shall not cost more than € 800,000 for each nominal MWt installed with 40% more selling thermal energy than that deliverable. Interesting integration of the combined-cycle version with biomass module mod. Brianza M.

- Electric Power: 4 to 20 MWel.

- Thermal Power: 4 to 200 MWt.

- Cycle: CHP Joule simple or combined.

- Fuel: natural gas.

- Feasibility study reference: LOMB1, LOMB2.

- Max electric efficiency: 39%.

- Max overall Efficiency: > 85%.

- Certification: CE / PED as a whole.

Range

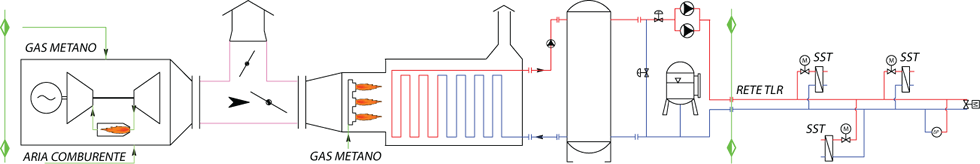

Mod. Lombardia 1

Natural gas CHP power plants (simple Joule cycle) with District Heating module.

| POS. | MODELLO |

ELECTRIC NOMINAL POWER (MWel) |

POTENZA TERMICA con fumi a 90°C (MWt) |

POTENZA TERMICA MAX con caldaie integrazione (MWt) |

RENDIMENTO ELETTRICO (%) |

RENDIMENTO GLOBALE (%) |

|---|---|---|---|---|---|---|

| 1 | Lombardia 1 - 5000 | 4,6 | 5,5 | 45 | 39 | 91 |

| 2 | Lombardia 1 - 9000 | 9,2 | 11 | 90 | 39 | 91 |

| 3 | Lombardia 1 - 14000 | 13,8 | 16,5 | 135 | 39 | 91 |

| 4 | Lombardia 1 - 18000 | 18,4 | 22 | 180 | 39 | 91 |

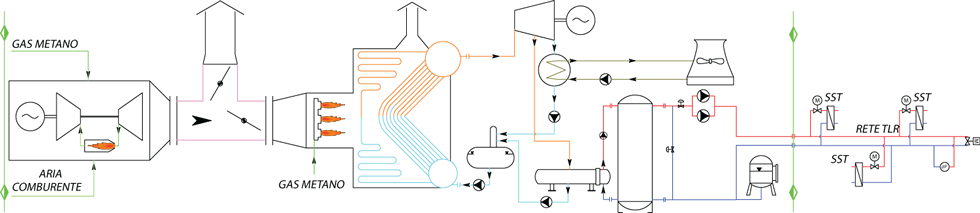

Mod. Lombardia 2

Natural gas CHP power plants (combined Joule/Rankine cycle) with District Heating module. 5 to 21 MWel and 4 to 17 MWt power ranges. Possible integration with fresh-air system up to twice as thermal energy generated. Models offered in combination with wood chips model Brianza M only.

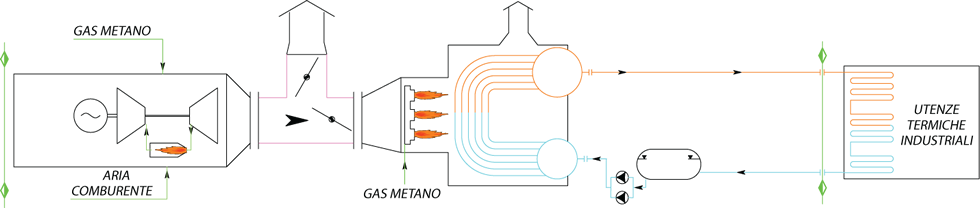

Mod. Lombardia 3

Natural gas CHP power plants (simple Joule cycle) with industrial steam generation module. 4 to 18 MWel and 5 to 22 MWt power ranges. Fresh-air system is provided in order to integrate thermal energy. Typical application in paper mills which use high amounts of saturated steam (3÷15 barg) in production cycle.

Working condition

| HOT WATER | SUPERHEATED WATER | COOLING | |

|---|---|---|---|

|

THERMAL DESIGN DISCTRICT HEATING CIRCUIT |

90/65°C | 115/65°C | 7/11°C |

|

MECHANICAL DESIGN DISCTRICT HEATING CIRCUIT |

PN16÷PN25 | PN16÷PN25 | PN16÷PN25 |

|

THERMAL DESIGN SUBSTATIONS SECONDARY CIRCUIT |

85/55°C | 85/55°C | 14/8°C |

|

NOMINAL PRESSURE LOSS SUBSTATIONS PRIMARY AND SECONDARY CIRCUITS |

10/3 w.c.m. | 10/3 w.c.m. | 10/3 w.c.m. |

|

FLUID SPEED DISCTRICT HEATING CIRCUIT |

0,5÷2 m/s | 0,5÷2 m/s | 0,5÷2 m/s |

| CENTRAL CONDUIT PUMPS HEAD | 0,5÷9 bar | 0,5÷9 bar | 0,5÷9 bar |

| PRESSURE LOSS POWER PLANT INNER CIRCUIT | 0,5÷1,5 bar | 0,5÷1,5 bar | 0,5÷1,5 bar |