- en

SHELL AND TUBE HEAT EXCHANGERS

Series "Novara"

Shell and tube heat exchangers

High Efficiency Recovery Boilers for hot/overheated water district heating networks through gases combustion from Otto cycle engines, Joule cycle turbines or industrial processes.

In order to increase the thermodynamic efficiency optional condensation modules are provided. Boilers are equipped with shut-off valves, control and safety devices, as well as electrical control panel, regulation, monitoring and data transmission, and are ready for remote control and integration with existing monitoring systems on free and unified protocols as well.

- Mod Brescia 1: water-tube

- Mod Brescia 2: fire-tube

- Thermal power: 2.5 to 50 MWt.

- Max flue gases temp: 550 ° C.

- District Heating max Temperature: 135 ° C.

- Max pressure: 25 barg.

- Certifications: CE / PED.

Range

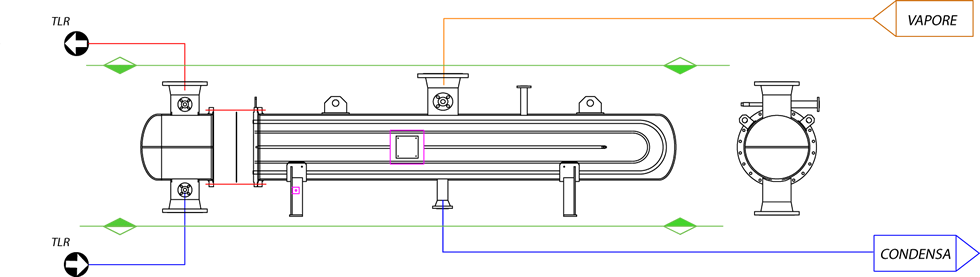

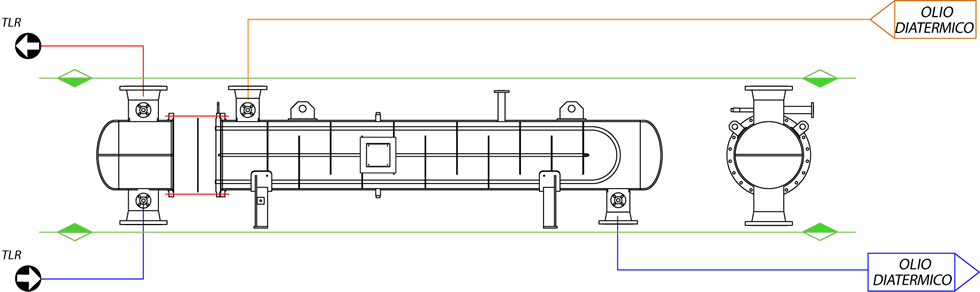

Mod. Novara 1/2

Steam/diathermic oil district heating Shell and Tube Heat Exchangers

| POS. | Model |

Thermal Power (MWt) |

Hot/Overheated water District Heating nominal Flow Rate (m3/h) |

Primary Fluid Hydraulic Design (barg) |

Secondary Fluid Hydraulic Design (barg) |

Steam/Diathermic oil design Temp (°C) |

Hot/Overheated water District Heating design Temp (°C) |

District Heating side Pressure Drop (bar) |

|---|---|---|---|---|---|---|---|---|

| 85 | Novara 1/2-50 | 5 | 172/86 | 10÷30 | 6÷25 | 135÷250/400 | 95/135 | < 0,5 |

| 86 | Novara 1/2-75 | 7,5 | 258/129 | 10÷30 | 6÷25 | 135÷250/400 | 95/135 | < 0,5 |

| 87 | Novara 1/2-100 | 10 | 344/172 | 10÷30 | 6÷25 | 135÷250/400 | 95/135 | < 0,5 |

| 88 | Novara 1/2-150 | 15 | 516/258 | 10÷30 | 6÷25 | 135÷250/400 | 95/135 | < 0,5 |

| 89 | Novara 1/2-200 | 20 | 688/344 | 10÷30 | 6÷25 | 135÷250/400 | 95/135 | < 0,5 |

| 90 | Novara 1/2-300 | 30 | 1032/516 | 10÷30 | 6÷25 | 135÷250/400 | 95/135 | < 0,5 |

| 91 | Novara 1/2-500 | 50 | 1720/860 | 10÷30 | 6÷25 | 135÷250/400 | 95/135 | < 0,5 |

| 92 | Novara 1/2-750 | 75 | 2580/1290 | 10÷30 | 6÷25 | 135÷250/400 | 95/135 | < 0,5 |

| 93 | Novara 1/2-1000 | 100 | 3440/1720 | 10÷30 | 6÷25 | 135÷250/400 | 95/135 | < 0,5 |

Mod. Novara 1

Mod. Novara 2

Working condition

| HOT WATER | SUPERHEATED WATER | COOLING | |

|---|---|---|---|

|

THERMAL DESIGN DISCTRICT HEATING CIRCUIT |

90/65°C | 115/65°C | 7/11°C |

|

MECHANICAL DESIGN DISCTRICT HEATING CIRCUIT |

PN16÷PN25 | PN16÷PN25 | PN16÷PN25 |

|

THERMAL DESIGN SUBSTATIONS SECONDARY CIRCUIT |

85/55°C | 85/55°C | 14/8°C |

|

NOMINAL PRESSURE LOSS SUBSTATIONS PRIMARY AND SECONDARY CIRCUITS |

10/3 w.c.m. | 10/3 w.c.m. | 10/3 w.c.m. |

|

FLUID SPEED DISCTRICT HEATING CIRCUIT |

0,5÷2 m/s | 0,5÷2 m/s | 0,5÷2 m/s |

| CENTRAL CONDUIT PUMPS HEAD | 0,5÷9 bar | 0,5÷9 bar | 0,5÷9 bar |

| PRESSURE LOSS POWER PLANT INNER CIRCUIT | 0,5÷1,5 bar | 0,5÷1,5 bar | 0,5÷1,5 bar |